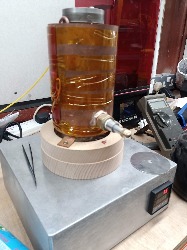

Wax Melter & Injector

In order to be able to create wax models for investment casting - a wax injector was required, this melts the wax and holds it at a specific temperature in a pressure vessel, this has a positive pressure of about 11psi, there is also a nozzel at the bottom that when depressed allows hot wax to issue forth under pressure into a rubber mold, once the wax has cooled and set the wax can be removed from the rubber mold and used in the investment casting process.

Here the first two pictures show the wax melter under construction, the main body is a peice of 4" (100mm) 14 gauge (2.5mm) copper pipe, the endplates are both 14 gauge (2.5mm) swaged copper disks that have been silver soldered to the main body, there is a thermocouple attached to the base of the pressure vessel, the heater is a commercial silicone heater pad and a pid controller that controls the heater via a solid state relay, the whole is insulated with 1" ceramic fibre and wrapped in an alloy cover, still need to make a top, but the machine is now operational, pressure is controlled by a precision regulator and there is a safety pressure valve that operates at 20psi ( nobody wants hot wax everywhere! )

Here the first two pictures show the wax melter under construction, the main body is a peice of 4" (100mm) 14 gauge (2.5mm) copper pipe, the endplates are both 14 gauge (2.5mm) swaged copper disks that have been silver soldered to the main body, there is a thermocouple attached to the base of the pressure vessel, the heater is a commercial silicone heater pad and a pid controller that controls the heater via a solid state relay, the whole is insulated with 1" ceramic fibre and wrapped in an alloy cover, still need to make a top, but the machine is now operational, pressure is controlled by a precision regulator and there is a safety pressure valve that operates at 20psi ( nobody wants hot wax everywhere! )

The rubber molds have been made by using 3d resin printers to produce the master model and this is then used to create a rubber/silicone mold for the wax casting.